Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

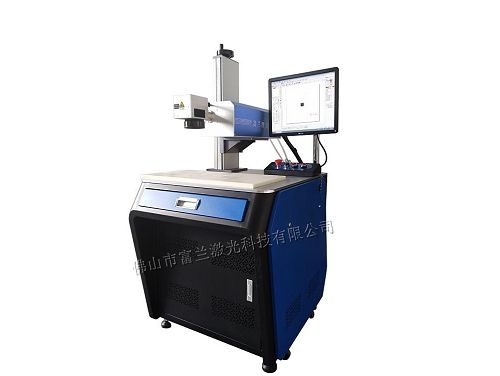

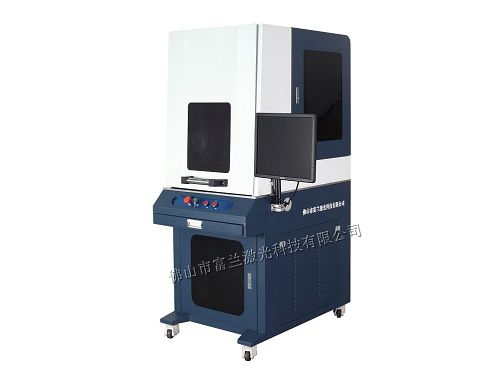

The laser wavelength of the ultraviolet laser marking machine is 355nm, and the laser is a cold light source, so it is often called cold light laser marking machine. The focus spot is very small, and the heat-affected zone of processing is very small, and the heat effect is very small during laser cutting or marking. It is more suitable for deep processing of materials that are more sensitive to thermal effects, so it can be used for ultra-fine marking, engraving, and marking of special materials. The applicable materials are very wide, which solves the problems of insufficient marking and poor effect of many materials with optical fiber, green light, carbon dioxide and MOPA laser marking machines.

Routine maintenance of UV laser marking machine is essential work. The manufacturer of laser equipment-Foshan Fulan Laser Technology Co., Ltd., referred to as Fulan Laser, has compiled a list of related matters that must be paid attention to when using UV laser marking machines. Let me share with you below, before you use the UV machine , First carefully read the following precautions, it will help you to use the equipment better.

1. Compared with laser marking machines with other light sources, the UV laser marking machine has stricter requirements on the operating environment:

①The working environment of the machine must be cleaned frequently;

②The working environment temperature of the machine should be kept at 16-28℃ and the humidity should be 45-75% (it is recommended to put it in an air-conditioned room, but it is not required to be placed in an air-conditioned room, as long as the temperature and humidity meet the requirements);

③Don't put it next to the equipment with large vibration of machine tools such as stamping;

④Environmental requirements for processing sites are smoke-free and dust-free.

2. The fluctuation of the power supply grid should be less than 10%. If it cannot be guaranteed, a voltage stabilizer must be installed.

3. Due to the low power of the UV laser marking machine (the UV laser marking machines currently produced by Fulan Laser are 3W, 5W, 8W), it is not recommended for customers to mark metals or materials that are hard and have marking depth The requested product.

4. If water cooling is used, pure water, deionized water or distilled water is required. Tap water, mineral water and other liquids containing higher metal ions or other minerals cannot be used.

5. The equipment should be well grounded and try to avoid machine vibration.

6. Do not use corrosive reagents to clean the parts of the machine, especially the optical components.

7. The conveyor belt connecting the cavity and the cabinet is fragile, please do not bend or be squeezed by heavy objects.

8. Please do not turn on and off frequently, and it can be turned on at least 3 minutes after turning off.

9. For machines that use casters and foot cups at the same time, after the position of the machine is fixed, please use the foot cups to support the machine. This can ensure the stability of the machine and avoid deformation and damage of the casters caused by long-term pressure.

10. Make sure that the heat dissipation of the machine is smooth, and no external heat is allowed to blow directly to the machine.