Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

Device model: HJ-GQCS200, HJ-GQCS300

Laser power: 200W, 300W

Pulse width: 0.1-20ms

Maximum peak power: 7kw, 9kw

Maximum pulse energy: 60J, 70J (optionally 90J)

Laser wavelength: 1064nm

Pulse frequency: 1-100Hz

Laser welding depth: 2.5 mm (sus304) /3.0mm (sus304)

Focal spot diameter: 0.3-2.0mm

Cooling method: water cooling

Power consumption of the whole machine: 9kw, 12kw

Power demand: 220V / 50Hz

Host size: 640 * 1305 * 1080mm

1. Optional CCD camera monitoring system, accurate positioning, real-time observation of welding process;

2. Adopt professional real-time energy feedback technology to ensure the stability of laser output energy;

3. Non-contact long-distance welding can be realized for the difficult-to-access parts;

4. The welding seam is small and smooth without pores, no need to be processed or simply processed after welding;

5. A variety of different waveforms can be set to match the welding parameters and welding requirements to achieve excellent welding results;

6. The focus spot is small, the positioning is accurate, and micro welding can be performed;

7. Welding of complex trajectories such as planes, circles and arcs;

8. Flexible placement, the host is separated from the worktable, and different worktables can be configured for welding processing according to the needs of different products;

9. The laser has the functions of energy splitting, time splitting, high-speed splitting, or both of which can be divided into common hours, which can realize simultaneous processing of multiple beams and multi-station processing to improve production efficiency;

10. Spot welding, butt welding, stack welding, sealing welding, seam welding and penetration welding can be realized.

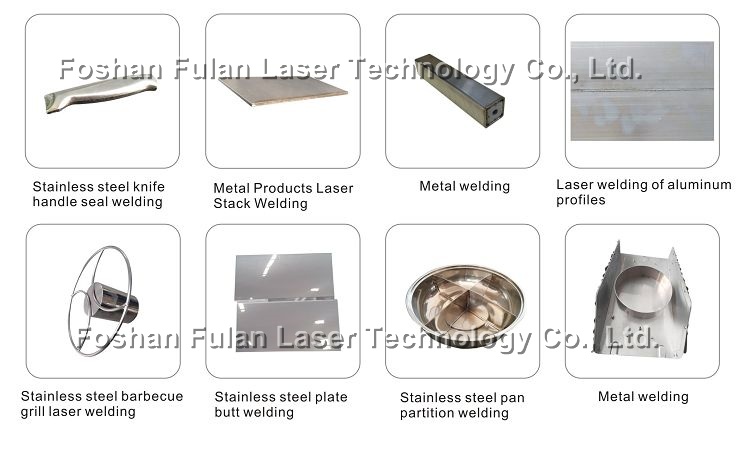

Mainly used for stainless steel, aluminum alloy, steel, aluminum, gold, silver and other metals, the same material welding and some dissimilar materials welding; widely used in precision 3C digital products, instrumentation, medical equipment, hardware appliances, jewelry, kitchen and bathroom, electronics Components, auto parts, craft gifts and other industries.