Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

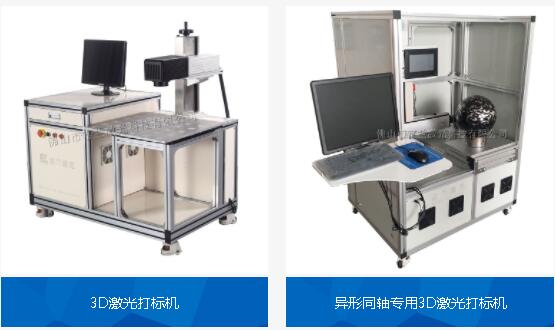

Because 3D laser marking can quickly change the laser focus and the position of the laser beam, it is possible to mark surfaces that cannot be realized in 2D. What are the advantages of 3D laser marking machine compared with 2D laser marking machine? Now, please follow Foshan Fulan Laser to have a look.

1. Large radian and irregular surface shape marking: for objects with a certain radian, or even spheres, to be exact, as long as the objects are coaxial, no matter what shape, the whole surface can be marked at one time, greatly improving the processing efficiency. The surface shape of many parts is irregular, and the height difference is quite large, so 2D marking processing cannot be realized. At this time, the advantages of 3D marking will be more obvious.

2. Marking of three-dimensional structure workpiece: In the current traditional 2D marking mode, the workpiece must be placed on the same plane, and the processing surface must also be on the same plane, in order to achieve one-time forming marking. With the characteristics of 3D laser marking machine, it is possible to achieve one-time forming marking when the workpiece has a height drop. Even on the slope, the processing consistency can be maintained. The process is reduced and the marking efficiency is improved.

3. Large range marking: 2D, the common maximum marking range is 300 * 300mm, while 3D laser marking machine uses larger X and Y axis deflection lenses, so it can allow larger transmitted laser spot, better focusing accuracy and better energy effect; If 3D marking works with the same focusing accuracy as 2D marking, the marking range can be larger; It can also be customized to achieve unlimited marking range.

4. Deep carving: There are inherent defects in deep carving of object surface by 2D marking. As the laser focus moves up during the carving process, the laser energy acting on the actual surface of the object will drop sharply, which seriously affects the effect and efficiency of deep carving. 3D marking for deep engraving does not have the above problems, which not only ensures the effect, but also improves the efficiency;

The 3D laser marking machine produced by Foshan Fulan Laser Technology Institute can use ultraviolet, optical fiber, CO2, green light, mopa, and end pumped laser sources, and is equipped with three-axis control technology, which can mark on the surface of high and low uneven planes, circles, arcs, and other special-shaped coaxial parts.

1.3D galvanometer has the characteristics of small volume, high accuracy, fast marking speed and good anti-interference ability;

2. In the dynamic marking process, the engraved lines have high accuracy, no deformation, uniform power, and no distortion of the pattern;

3. The marking format shall reach 800 * 800mm, meeting the use requirements of large format engraving.

4. Change the position of the focus axis to perform depth engraving.