Foshan Fulan Laser Technology Co., Ltd.

National Hotline: 0757-29899345

Manager Wen: 18902563402

Fax: 0757-29899345

Business QQ: 2801827697

E-mail: china@fsfulan.com

Address: No.14, Leliu Port Intensive Industrial Zone, Shunde District, Foshan CityThe high-tech zone almond altar town, shunde, foshan city shun industry west road no. 15 cimc valley 20 9 / f, building B

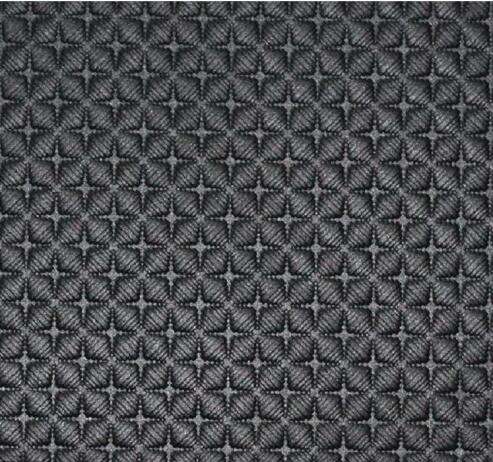

Sun patterning (also called biting, etching, etching) is a common process for mold surface treatment, which directly affects the appearance and surface strength of the product surface. At present, there are two main types of mold sunburning processes: one is medicine sunburning, and the other is laser sunburning. Now, let's follow Foshan Fulan Laser to learn about these two processes.

1. Potion sun pattern

Processing flow: degreasing and washing molds→film drying→filming→exposure→chemical inspection→surface treatment→printing treatment→flower repair treatment→chemical etching→surface treatment

This traditional sunburning process relies heavily on manual processes. The etching factory generally only provides standard textures for customers to choose. Many patterns cannot be realized or are easily distorted. Even if a suitable photochemical film is used, wrinkles are unavoidable and must be finely processed. Follow-up processing. Moreover, the raw materials and processing waste used in the sunburning process will cause great pollution to the environment. With the development of society, modern molds have higher and higher requirements for texture processing and more and more complex patterns. Obviously, traditional manufacturing processes have greatly restricted the ideas of product designers. Differentiation of market products.

2. Laser patterning: It is the use of laser marking machine for etching, the principle of using laser to etch the metal surface of the mold, and the various effects obtained by etching the mold surface.

Processing flow: degreasing and washing mold → drawing → laser processing → gloss treatment

The emergence of laser marking texture processing technology has brought innovation to mold surface processing. Utilize the perfect combination of digital texture design and laser marking technology to make everything possible. From digital computer design to generating program, the fidelity of any graphic texture can be guaranteed, and then imported into laser marking machine equipment for processing, using laser for ultra-fine processing, so that everything can be achieved, and the appearance of the product is unique. Let the endless imagination of the appearance of the product come true.

Below, we will compare these two processes from the following aspects:

1. Environmental protection: chemical sunburn: chemical potion is used, which is not environmentally friendly;

Laser streaking: No chemical medicine is needed, environmental protection.

2. Accuracy: Chemical sunburn: it will produce side erosion and tooth edges, which can not achieve repeatability and uniform processing; the surface is rough and the three-dimensional impression is poor;

Laser printing: no side etching and tooth edges, repeatable and one-stop processing can be achieved; fine surface, particularly strong three-dimensional impression;

3. Requirements for materials: chemical sun pattern: The requirements for mold materials are particularly high, and only materials that meet the requirements can be used for chemical sun pattern;

Laser printing: It can be applied to any material, and the requirements for mold materials are low.

In short, the traditional patterning process has many procedures, high consumables, insufficient texture and long production cycle. However, the use of laser marking machine for patterning processing can not only make up for the shortcomings of traditional process processing, but also has many Other advantages.